Iron-on heat transfer vinyl enables you to apply any custom design to fabric by the use of heat and pressure. It gives good results when applied using the HTVRONT heat press machine, as it will bond, be smooth to apply, and be durable. It is a very easy process, which makes it fast and easy to produce professional-looking designs.

Desire impeccable wash-after-wash designs? However, when used in combination with the HTVRONT heat press machine, iron-on heat transfer vinyl will get easy and provide you with clean and professional results every time. Your ideas of creativity are just realized in a few minutes by using the appropriate heat and pressure.

The heat transfer iron-on vinyl is a quick method of personalizing clothing and fabric products. Application of designs is made easy using the heat press machine, which is called HTVRONT heat press, to provide a smooth look inside and outside. It is suitable for the beginners as well as the followers of the creative field.

What is heat transfer vinyl that sticks on with an iron?

HTV is a special kind of vinyl, sometimes known as iron-on heat transfer, and attaches to fabric under the influence of heat and pressure. It has an adhesive sticky that is activated by heat, and the design attaches itself to the surface. During the customization of t-shirts, hoodies, tote bags, and numerous other projects related to clothes, HTV is extremely popular.

The content is meant to be easy and lightweight, thus flowing with the cloth. This renders the designs comfortable to wear and at the same time does not lose their shape and color with time.

What makes the HTVRONT Heat Press Machine a good choice?

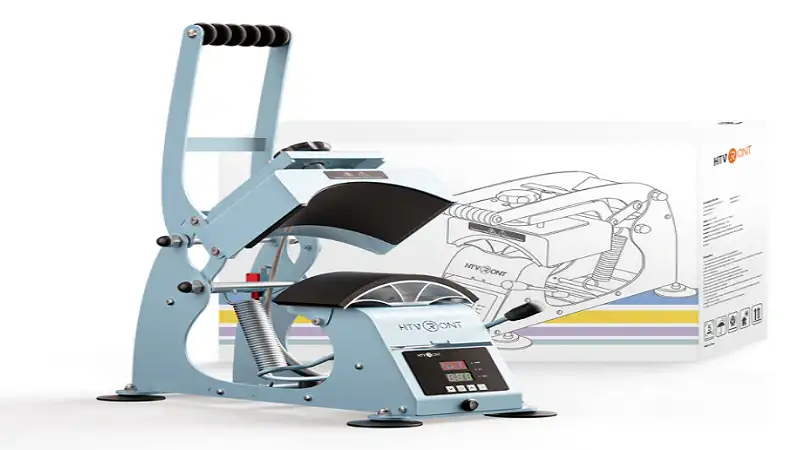

The HTVRONT heat press machine is aimed at providing uniform heat and pressure, which are major elements of successful vinyl application. A heat press has constant temperature settings and exerts pressure in all parts of the design, unlike a household iron. This eliminates frequent problems like peeling edges, disproportionate bonding, or fading.

Advantages of Iron-On HTV and HTVRONT

Applying iron-on heat transfer vinyl and a heat press machine, which is HTVRONT, provides a number of benefits, enhancing quality and efficiency.

- The main benefits of such a combination.

- Provides good adhesion of strong vinyl.

- Minimizes the lifting or cracking of designs.

- Saves time because it presses very fast and in a regular fashion.

- Delivers professional-level results.

Such an arrangement enables users to be more creative and less troublesome when it comes to solving errors in the applications.

SAP successful application

Iron-on heat transfer vinyl is one vinyl that can be greatly achieved with good preparation. It is as simple as drawing your design or choosing a design and cutting it using an appropriate cutting machine. Consider the design prior to cutting, as the HTV is applied face down on the fabric.

1. Possess the Design and Fabric

Design and print your picture, then cut the vinyl and weed it, and then pre-press your fabric to get rid of all moisture and wrinkles.

2. Apply Heat and Pressure

Lay the vinyl on the cloth and apply the HTVRONT heat press machine at the correct temperature and pressure to make a smooth and firm transfer.

3. Cool, Peel, and Set the Design

Allow the vinyl to dry, as suggested, and carefully remove the carrier sheet, and apply a final quick press, which may be applied to assure durability.

Common Mistakes to Avoid

Despite the quality of tools, one can make mistakes when there is a failure to take simple measures. The use of the wrong temperature or pressure settings is one of the problems that may frequently occur, leading to the peeling of the vinyl or its inability to bond. Never disregard the instructions on your particular HTV.

The other error is that of not doing the pre-press stage. The fabric surface can be moist and full of wrinkles, which will disrupt adhesion. Even a few seconds spent on preparing the fabric can make the design much more durable and look better.

The custody of Heat Transfer Vinyl Designs

The quality of iron-on vinyl designs is significantly influenced by care. The state of the garment after the application should be drying for a minimum of 24 hours. The cold water washing inside out helps in safeguarding the design, and good heat in the drying would not cause damages. These suggestions in the care instructions can be followed to ensure that the design is smooth, lively, and well adhered to upon various washes.

Who Will Be Beneficiaries of This Setup?

The iron-on heat transfer vinyl with the HTVRONT heat press machine is a combination that is appropriate for a large number of users. Novices like the simplicity and predictability, whereas expert artists like the predictable outcomes. This arrangement will enable small business owners to make personalized products efficiently, and hobbyists can create personalized gifts and apparel.

Conclusion

Iron-on heat transfer vinyl is a simple but efficient method of customizing clothes, and combining it with the heat press machine, the HTVRONT machine, makes the procedure a notch higher. This combination is designed to give a user confidence in clean and long-lasting designs with the consistency of pressure and easy operation of heat.

FAQs:

1: What is so special about the HTVRONT heat press that makes it the best choice when ironing on vinyl?

The HTVRONT heat press delivers constant heat and consistent pressure, which assists in smoothing out the vinyl that prevents the formation of bubbles or purification.

2: What is the duration of ironing on vinyl using an HTVRONT machine?

The majority of designs require 10-15 seconds of press time, although the vinyl guide is always the best guide.

3: Why does my vinyl not last after washing?

This normally occurs as a result of low heat or pressure; the right settings on the HTVRONT press increase the durability.